Because carbon fibre is generally black and invariably proffering a hi-tech look, furniture and lighting made from this ingenious material has never been a particular favourite. It's striking, even sexy if your into that sort of sci-fi look but for all its luscious curves and jaw-dropping spans is it really a material that should be used in furniture, lighting and other inters related objects? Well, the answer is sometimes - but only when its not used gratuitously. I guess this is true of many materials - even wood where chairs carved from massive blocks of a precious timber (Riva 1920) or where sinuous forms are created by joining dozens of c'n'c milled parts together (Giorgetti's Rossella Pugliatti designed 'Move' rocker) feel excessive and to be honest, quite gauche. Just because a company has the technical ability to do something doesn't mean they should. Design daily has compiled a personal selection of interior products made from carbon fibre that really use the material in interesting ways, often to produce results that would be difficult or impossible to achieve in any other material.

When it comes to making items with immense strength while being incredibly light, carbon fibre is right up there. When carbon fibre is added to polymer to create carbon fibre reinforced polymer (CFRP) it has up to 10 times the strength of steel, is twice as stiff, while being just a one-seventh of the weight. Engineers have been building bridges with the material as early as 2008 (although to date the spans are still quite small) and the inspiring Japanese architect Kengo Kuma has used the material to tether a Japanese textile company building to the ground in an earthquake zone. Even Melbourne's towering West Gate Bridge that spans 2.5 kilometres has had its concrete and steel construction strengthened with the stuff in 2011.

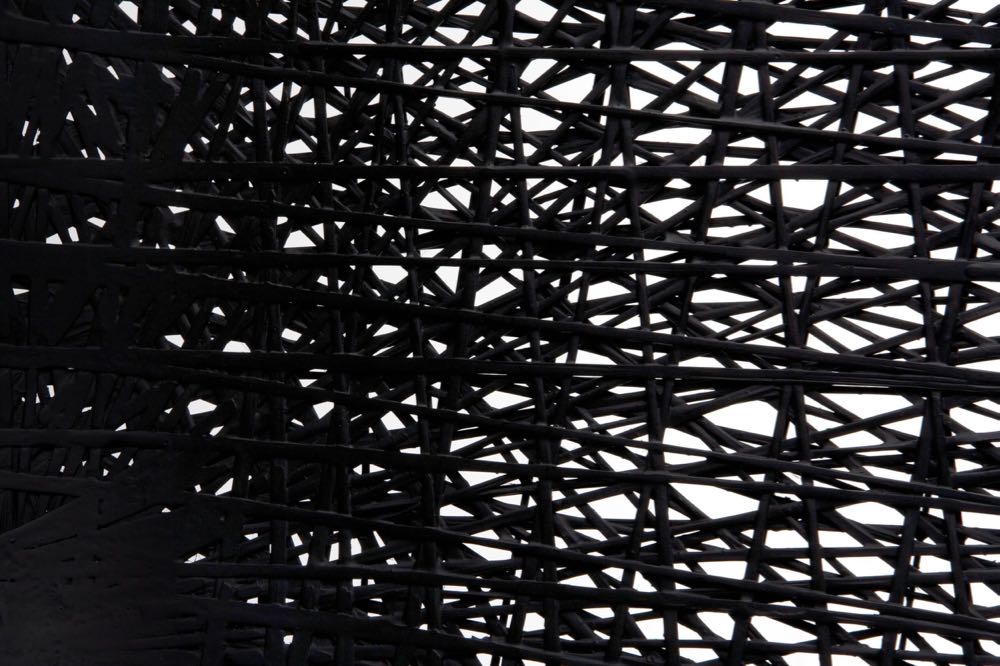

More recently the University of Stuttgart under the leadership of Achim Menges has created the Elytra Filament Pavilion from woven glass fibre (white bits) and carbon fibre (the dark bits) that was displayed in the courtyard of the V&A Museum in London at LDF 2016. The overarching inspiration for the installation was Victorian Greenhouses but the weave pattern was inspired by the forewing shells of flying beetles nknown as elytra and was made by a specially developed robotic weaving machine. This project was a collaboration between Menges, Moritz Dörstelmann, Jan Knippers and Thomas Auer.

You can obtain a good basic understanding of the project and the use of robotics in continuous carbon fibre weaving in the short film below.

The first time I was bowled over by an item of furniture made from carbon fibre was when I clapped eyes on Marcel Wanders' 'Knotted' chair at the Vitra 100 chairs exhibition. Designed in 1996 for an exhibition called Dry Tech 1 presented by the Dutch design organisation Droog, the chair is made from an aramid fabric sheath with a carbon fibre core. It is hand knotted within a frame and its floppy macrame style form is then impregnated with resin. The design uses gravity to create its unique scooped shape and because of the sheer strength of carbon fibre (CFRP) it defies any normal structural requirements. Weighing just two kilograms it was once demonstrated to me by a cheeky salesperson at Sydney's Dedece, by turning it upside down and standing on it. As I wanted to buy that particular example as it was in a sale, I was relieved that it survived totally unscathed! Apart from the obvious strength to weight achievement the Knotted chair (produced by Cappellini since 1997) is particularly successful because it doesn't appear to be hi-tech. There is no gleaming carbon fibre to be see just a thin rope-like material in a very pleasant shade of khaki green.

‘I wanted to make a product that doesn’t look industrial, a design that shows that it is lovingly made especially for someone, with the same kind of aura as an old worn down wooden cupboard. Knotting is a technique with which you can achieve this artisan atmosphere.’

Marcel Wanders

(Quote from an article in Eigen Huis & Interieur, November 1996)

"I doubt I will ever do another project in carbon fibre - its not the most environmentally friendly material but for those chairs that are already out there the owners should be really happy as they are pretty indestructible. I Hope they appreciate this and never throw them out. I understand the process extremely well now and have it up my sleeve so maybe I'll bring it out again one day - who knows"?

Bertjan Pot

The third item made from carbon fibre that in the opinion of Design daily harnessed the qualities of the material completely was the 'Surface' table by Terence Woodgate and John Barnard for Established & Sons. Designed in 2008, this incredibly minimal table has impossibly fine legs at the very edge of the table top yet can support a person standing in the middle of it. Manufactured in lengths up to 6 metres it is the perfect boardroom or over-the-top dining table, seating up to 24 people. The surface of the 'Surface' table is a mirror polished sheet of carbon fibre. Taking its lead from British expertise in motor racing technology the brand produced a table and matching chair that offers a seamless mono-material solution. While the edge of the table appears impossibly thin it is in fact the start of a 'V' which becomes increasingly deep as it approaches the centre. The high gloss finish has been compared to Richard Wilson's artwork 20:50 that reflected an entire room in a shallow pool of sump oil.

One of the leaders in what I would describe as fluid futurism has always been Ross Lovegrove. No matter what material he is using he seems to bring a plasticity to the form that is quite sensual. His 'Moot' chair for Established & Sons (above) gets its rather odd name from the expression "Mood Of Our Time". Its complex shape is seductively smooth and curvaceous with a nod to the flexibility of the human body as the seat bends back on itself. According to Established & Sons the design could not be realised in any other material but carbon fibre.

Another designer with a love of impossible shapes and composite materials is Australian-born, London-based Brodie Neill. His 'Jet desk' which dates from 2008 appears to take it's lead from sea creatures with squid-like tentacles forming the support for the ovoid desk top. The desk was a private commission by Swarovski and uses their crystals on the inside of the leg structure. to create what Neill describes as a "jewel-box feel".

Michael Sodeau is a British designer whose work in timber is particularly well known. A contemporary of Barber Osgerby he has worked for UK based companies such as Isokon, Modus and Casper Limited Edition but also for Italian brands Gervasoni, and Salviati and Swedish brands Offecct and Swedese. The 'Halo' chair exploits the first coloured carbon fibre material developed by Hypetex, a leader in materials for Formula 1 racing. The chair is a recipient of the coveted Red Dot Design Award. The shape is quite revolutionary but due to careful moulding, extremely comfortable. It is available in red, blue black and yellow plus platinium silver.

Another Brit who has turned his hand to products made from carbon fibre is MIchael Young. Based in Hong Kong, Young was commissioned by US brand Coalesse to design a mass produced chair in carbon fibre. The 'LessThanFive' chair was the result. At just under 5 lbs (or 2.3 kgs) it's not the lightest carbon fibre chair in the world but by anyone's estimation this is still incredibly light and the design not only stacks but will support up to 300lbs (138kgs). Like Michael Sodeau's 'Halo' chair, the 'LessThanFive' is available in a variety of colours. Carbon fibre furniture is a completely different entity to injection moulded plastics where chairs are produced at the push of a button. Carbon fibre is miraculous in many ways but requires serious investment in tooling, materials and facilities. You can watch a video on the incredible painstaking accuracy required to produce the chair below.

South Korean designer, Il Hoon Roh settled in London in 1991 where he studied architecture, receiving a diploma from the Architectural Association School of Architecture and a Masters in Design Products from the Royal College of Art. He worked for Foster and Partners as an architect and later became a part of the Royal Institute of British Architects. In 2010, he started creating functional sculptures and established his own studio in London. In 2013, he moved his studio to the heart of Seoul, within an industrial zone, where there are a large number of specialised workshops are at his disposal.

Due to the complexity of the process used by Il Hoon Roh, Design daily has chosen to lift the following words directly from his website so as not to misinterpret the method:

Carbon fiber, coated in resin, is a light and resistant material, which must be refrigerated, used, and manipulated at an optimum temperature of 23 °C. It needs to be heat treated in order to acquire its ultimate characteristics of solidity and resistance, coupled with incredible lightness. Carbon fiber is presented as two large sheaths appearing as rolls of fabric which Il Hoon cuts into bands, folds in two, then twists in order to obtain filaments that he braids to create a structure that resembles a honeycomb. This braiding is executed to create a perfect tension at the heart of the structure, and designed like industrially precise steel webs, at the heart of which he will link the filaments with virtuosity and craftsmanship.

Japanese designer Nendo loves nothing more than to reduce his designs down to a gesture or fine line. With his 'Nest' shelving from 2015 he used carbon fibre instead of his normal material of choice - steel, to produce shelving that is capable of expanding and contract simply by pushing or pulling from the units side. Essentially an inner sleeve of shelves slides effortlessly into an outer sleeve. In typical Nendo fashion this appears to be something of a magic trick but really it comes down to the choice of material. Carbon fibre allows for a very thin wall thickness that requires no bracing so very little space is wasted. The material is also extremely light so can easily be moved. The rest is down to the genius of Nendo.

.

Well known for his organic shapes, Marc Newson designed the 'Black Hole' table (above) early on in his career in 1988. Only twenty units of the table were produced at that time by Japanese surfboard makers who had some experience in the use of carbon fibre. Newson had met these makers while living in Japan but was never very happy with the way they were executed as the underside of the table was made using standard fibreglass and the legs were cast and added as a second phase.. In 2000 he re-editioned the table with the help of a French aerospace company and the table was made totally in carbon fibre without the legs being integral to the form.

Marc Newson's Carbon chair from 2008 above left and the Surface chair by Terence Woodgate and John Barnard show the diverse approaches that are realised in carbon fibre. Newson's chair references black holes and plays with voids while Woodgate and Barnard's chair is all about minimalism.

With a large amount of experience in carbon fibre technology New Zealand designer Jamie McLellan could have designed objects in carbon fibre with complex biomorphic forms but instead he chose to create a light that expressed the lightness and extreme thinness of the material. HIs 'Fibre Light Funnel' pendant designed in 2014 appears to be made from laser cut metal but is virtually weightless. The light is available through New Zealand company Resident.

Thomas Freichtner's 'Carbon' lounge chair (above left) and Marcel Wanders' 'Carbon Balloon' chair (above right) both use rewoven sheets of carbon fibre but to completely different ends. Freichtner's chair becomes a geometric sculpture while Wanders' chair literally encases sausage shaped balloons for a cheeky contradiction of materials and strength overlaid with a healthy dose of absurdity.

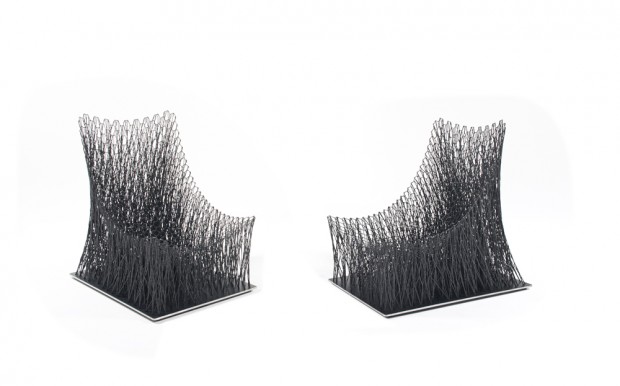

Dutch brand LABEL/BREED create unique products through involving outside manufacturing companies from the very earliest stages of a design. Designers are selected and then encouraged to seek out a material and manufacturer that understands that material intimately. This often leads to situations where the company has never previously been involved in producing furniture lighting or any other domestic object but this helps to create interesting new outcomes. Marleen Kaptein is one of the designers from the LABEL/BREED stable and in recent years she has produced a number of products using carbon fibre. Her 'Fibre Placement Chair' from 2015 shown above while a beautifully resolved design is too expensive to mass produce and so has become a limited edition piece with twenty in the edition. in response the designer has produced a dining chair that uses carbon fibre sheet material rather than individually woven fibres. While both are done by advanced robotics the length of the carbon fibre used is quite different. The lounge chair requires a continuos 'string' of carbon fibre while the dining chair utilises short off cuts, making it much less to produce.

Engineer, fine woodworker and architect Matthew Strong is from Detroit Michigan, USA. His 'Carbon Eames Sofa' pays homage to the design icon of the 50's albeit in a stretched and highly patterned form. By using carbon fibre tape, Strong was able to produce a very open weave with similar strength to that of the original glass fibre shells made by Herman Miller. The forces in the centre of the seating area must be quite immense but due to the carbon fibre leg bracing the sofa doesn't fold in half. I imagine the Eames' would have been pretty excited by carbon fibre if it had been around in their time. The duo had experimented with materials for aviation many times in their careers and loved to bring new techniques and materials to everything they became involved in.

Carbon fiber - not everyones idea of beauty but an incredible material none-the-less.